Boogie, a good, bad, and shoes.

Many boys begin to think about the construction of shoes when they go through the first round of their disposable clothing shoes. You know these people – look quite decent out of the box, but after six months, like a single peel or a leather paper. This question arises: What do some shoes maintain for years, while others are at night? And is it directly related to the price?

The answer, often, comes to the point of how to be associated with the single upper. This connection – its method and its content – have to do with branding or even longer than leather quality.

The important thing is, every construction method, even the most or less sustainable, has its profession and compliance with it. What is intended for what is used for shoes really determines whether the construction used was based on stability or cost cutting.

Before going into construction methods, we need to start with quick primer

Basic shoe anatomy

Upper

It is the sole material that covers the feet – usually leather or canvas. It contains ingredients such as vamps, heels, springs and more.

Insole

The surface of the shoe on which your foot is tied. It can be applied in a row of cushions, garbage, or leather in terms of design.

Out civil

Under the shoe that touches the ground. Outs can be made from leather, rubber, or artificial combination.

Welt

A strip of leather or other material that sits on high quality shoes between the upper and the outskirts. It plays a key role in stability and ability to solve.

Conclusive

3D model of one foot used during construction. The final shape and structure determines how the final shoe fits and visible. Within a brand, different shoe lines can use different last items, which in turn fits different, and can be mentioned in the product description.

Different ways of building shoes are not merely “good” or “bad”, or quality. Understanding which method can be used best for a shoe can help you make strong purchase decisions. Know How Spending on shoes will save you from spending More On the shoes

Construction of cold cement

Invention: The middle of the 20th century (larger adoption after WWII), spread with artificial adhesive things

Cold cementing is the standard way to connect out -sols to most of today’s athletic and fashion shoes. It uses strong synthetic adhesive items to tie the upper or midsol unit to a rubber or foam out civil.

After the upper of the shoe is deposited (often with stroke stitching, down, or other internal methods), the single unit is sticking to the use of high -strength cement. The bond decides without heat, and allows the brands to use modern foams such as EVA, Felon, or polyurethene that melts or damages under heat.

What works: Running shoes, trainers, street ware shoes, clothing shoes, foam cushions casual shoes. Cold cementing enables light material and complex single design with air units, flakes drains, or shielded shapes.

What not: Cold cement shoes are not designed to solve. Once the adhesive bonds or foam cushions are gone, the shoe occurs effectively at the end of its life. Stability varies in terms of use, but repair options are limited.

Factors such as glue type, how well the material is prepared, and how much pressure and time is used while suppressing all influence stability. Bouncing measures or using cheap material can lead to skin disasters.

Cold cement is different in standard, and unfortunately, it is not always easy to find the difference, but it contains some indicators. Improved cold cementing shoes, such as well -known athletic or lifestyle brands, use strong adhesive items, prepaid material properly, and often add design such as cups of cups that wrap the upper for more secure bonds.

This method itself is not naturally weak, but its implementation makes all differences.

It is generally safe to say that if a product page has not mentioned the construction procedure, it has probably been cement – especially for less than $ 200 shoes.

Most brands highlight Gadre Welt as a place to sell (below) as a salesman because it increases value, longevity and resilience eligibility. Cemetated construction is cheaper and faster for construction, and brands using it often focus on marketing on styles, relief or materials on how to be linked.

There are exceptions-some small or heritage-affected brands may not be a clear list of it, or black stitching shoe can fly down the radar-but In the mainstream retail, no mention is usually seminated.

How to find it: There is usually no sewing around the out civil (or if its decorative and rubber is shielded), only a smooth glue bond where the only upper is found. Slowly softening the shoes can reveal separation on a cheaper couple or a glue glue line.

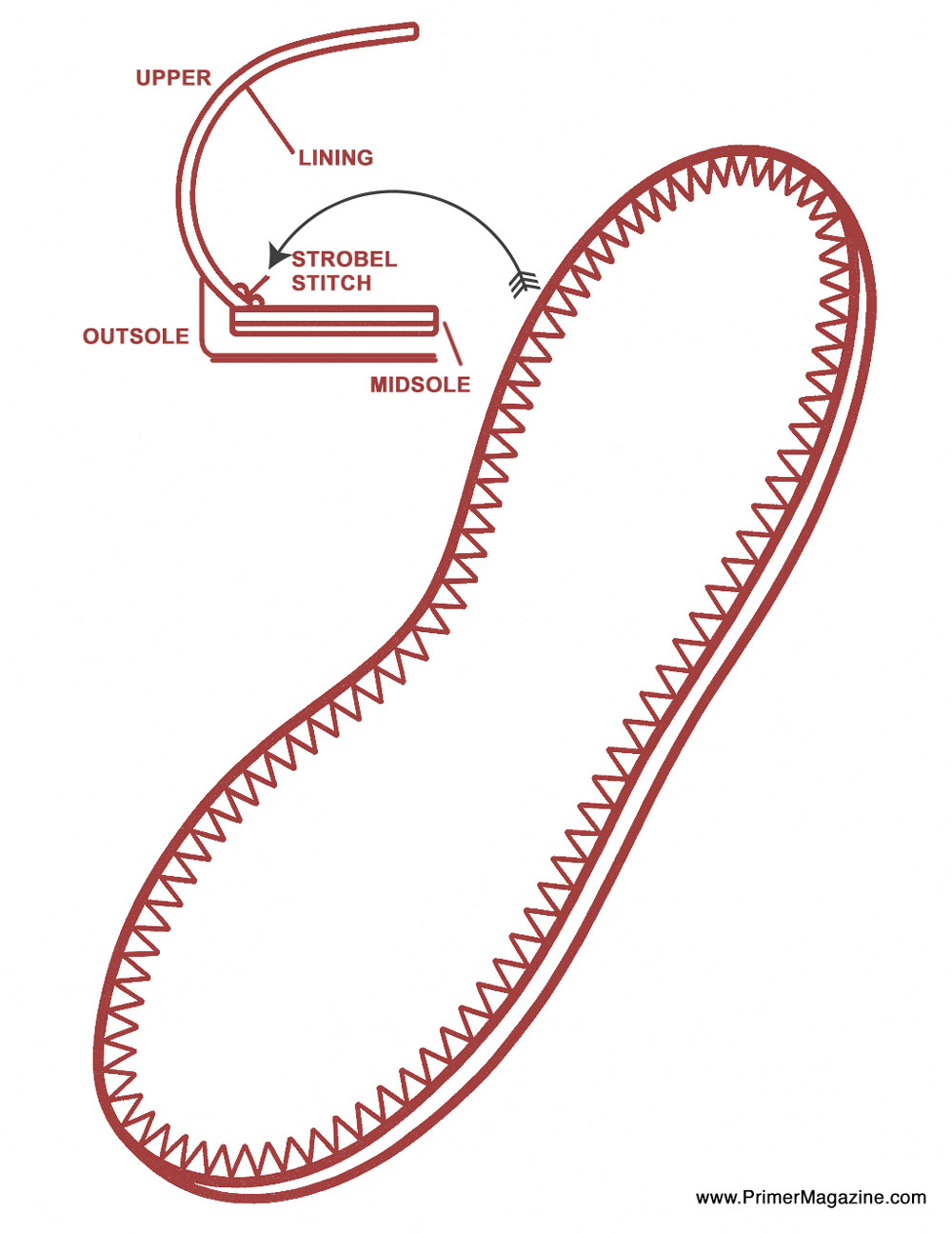

The construction of the stubbles

Invention: Mid -1900s, named the Stroke Machine Company in Germany

Stroke construction refers to how the upper unit is linked to Ago Apply only. In this procedure, a fabric is stitched directly on the upper edge of the upper upper, which makes a flexible, sock base. This is stitched upper unit Again Usually cement is on the cool outout.

Stroke is often hidden for the buyer – not under the shoes, it is under the foot. But this is one of the major reasons that performance shoes feel soft and flexible compared to leather clothing shoes.

What works: Ideal for shoes where flexibility, light weight and broken feeling are essential. Think about Nike’s free or flying lines, or mostly modern running shoes. Construction allows natural feet movements and breathing.

What not: Struggle built -in shoes are difficult to repair. There is no welt or structural basis to solve. Just like the construction of a cold cement, once wears a single or the cushioning is flat, the shoes have to be changed.

How to find it: You may not see it from the outside, but if you lift the enrollment, you can be seen connecting the zig zag stitching to the bottom thin fabric layer.

Black construction

Invention: In 1856, Liman Red Black, who worked for the singer sewing machine company.

Smooth and sleek, the upper is wrapped under the insole and all the layers from the inside sew directly with the same stitch. It is the product of industrial revolution and is still common in Italian shoes today.

What works: Slim profile clothing shoes where you want a clean edge and lightweight, elastic feeling. Black construction also allows to be resolved – as long as Mochi has the right equipment.

What not: Goodier (below) is less resistant to water, and interior stitching can sometimes be felt under the feet. Not everyone can work on them, which restricts repair options in some areas.

How to find it: Look inside the shoe, if you feel stitching under the insul but does not see any side along the edge of the sole, it is likely to be black.

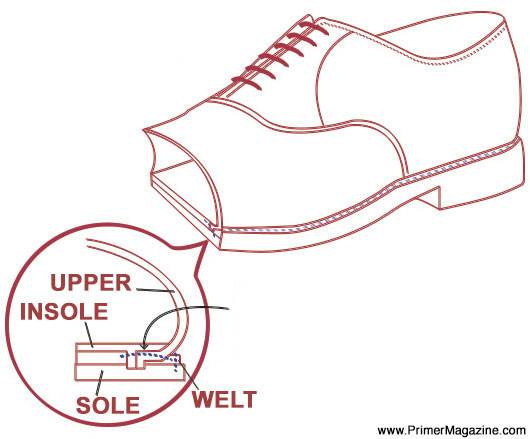

Willented construction

Invention: Charles Good Air Senior’s Vulcanization process based on the 1800s (patent in 1844)

Common in canvas shoes like van and conversation, this process binds the soles of unmanned rubber with the upper, then Backs The whole shoe in the vilking oven. Heat, about 230 ° F, tighten the rubber in a durable, spring sole and locks it on the upper Without Stitch or glue.

What works: It is ideal for heat -avoiding materials such as canvas, suede or leather. The result is flexible, pleasant and perfect for skateboarding or streetware.

What not: Volcanization limits the material selection. Anything that can melt like a nylon or ava cannot be used. It also requires a special factory setup, so production is often more niche. You will not be used in high -end clothing shoes, and it is not designed to solve.

How to find it: The rubber side wall is wrapped up on the top of the upper stitch, and the whole shoe feels spring with a slightly rubber smell, again, thinking about the van or the conversation.

Goodier Welt Construction

Invention: Charles Good Air Junior was patented in 1869 (Rubber Vulcanization cow’s son)

Classic quality for durable, repair shoes. The upper and insole is sewn on a leather welt: a strip that runs around the shore. After that, another stitch is connected to the Out Civil. Among these layers? A bed of cork that molds your feet over time.

What works: Clothing shoes, oxfords, broogs, or anything you want to wear for a decade. Good air shoes are made to solve repeatedly.

What not: The extra structure adds weight and hardness. It takes time to break before comfort. Usually more expensive, but for good reason.

Some brands also use a hybrid called Black Rapid, where the upper black is stitched on a midsol, after which it is sewed on the outsiders.

How to find it: Find a visible sewing around the edge of the Out civil and a small drop where the welt is slightly spread. These shoes feel structural and weighty.

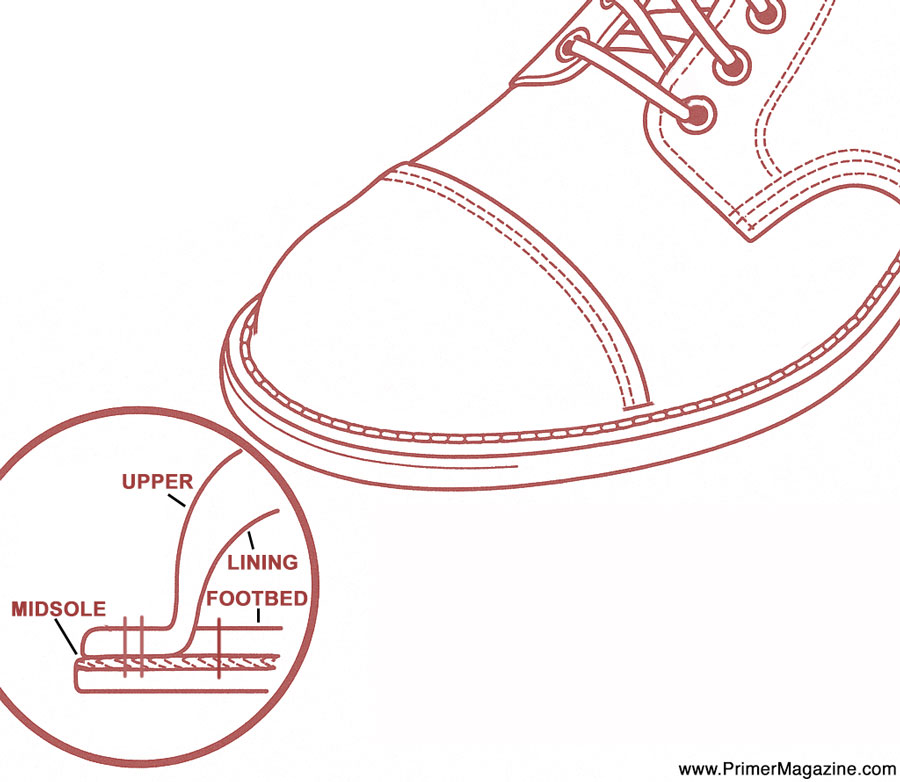

Statch Downt Building

Originality: With strong roots in traditional boot -making, American workwork and Pacific Northwest Heritage Brands

The upper outskirts are flared up and sewed directly on midsol or outlis – no welt is used. It produces a wide, visible sewing frame where the upper layer goes out and becomes part of the single structure.

What works: Go for uneven, water -to -water shoes. Brands such as Veberg, White, Nick, and Danner have made the synonym for stability synonymous. It also appears in lower -cost models such as Clark desert shoes and some red wing offerings, though the quality is different.

What not: It can be difficult to solve. If a cobbler does not reuse the original sewing holes carefully, it can damage the burning leather and compromise with the upper. Not every shop is equipped with cleaning. Usually you have to send them back to the brand to work.

How to find it: Search the upper leather in which the outer and stitched flats look against the edge of the sole – there is no welt, just rough leather and thick sewing around the base. The profile is wide, and the aesthetic bent is overwhelmed and active.

Norwegian (Hurricane Welt) construction

Originality: Traditional European boot -making

A heavy duty variation to welcome good yares, a visible double stitch has been used in the construction of Norway that passes through the upper and welt, then goes out to out. It also often offers a raised storm welt that rotates upside down with the frame, adding resistance to water. The basic construction is still good. Storm Welt has a specific style of welt used in this process.

What works: Alpine style shoes, winter dressed shoes, heritage workware.

What not: Blackier profile and high cost. Often more style than everyday shoes.

How to find it: You will rotate two rows of sewing and shoes, making it a chickened, more uneven profile.